Under construction, please look forward to it

نصائح دافئة

Tips

Tips

Please improve your information and become a senior member

Tips

نصائح دافئة

Tips

Trusted stores

Trusted stores

Direct sales

Direct sales

Instant prices

Instant prices

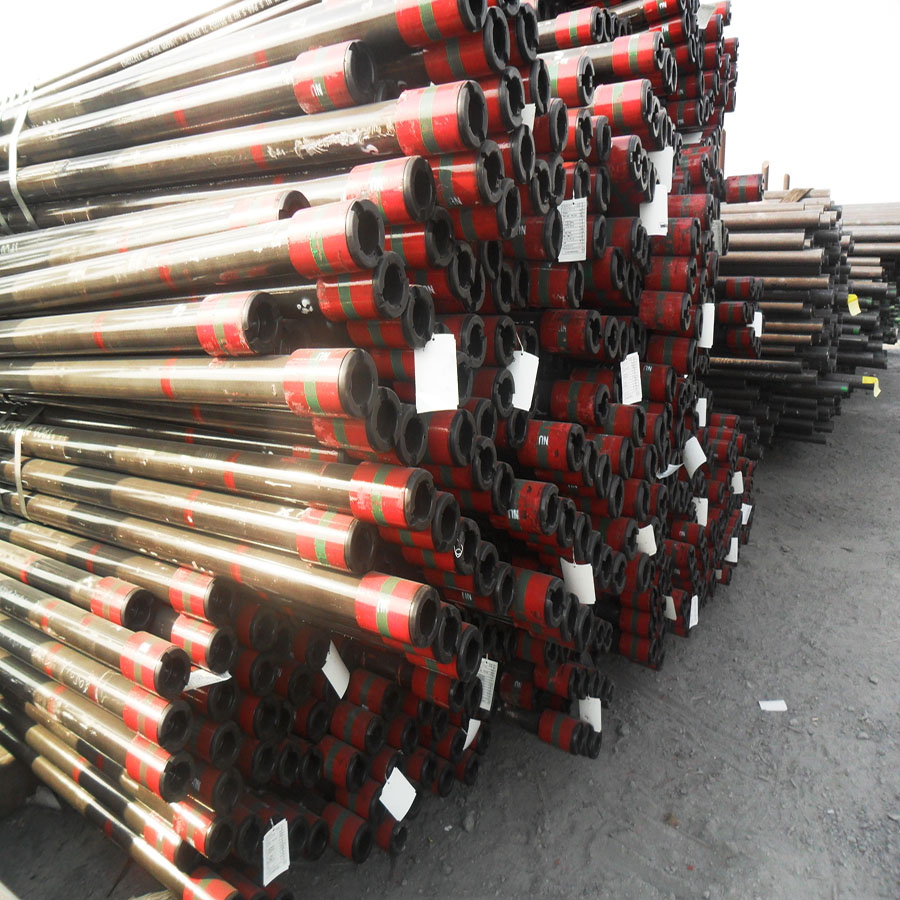

product

Tubing Dimensions: 1.05” to 4-1/2” with End Processing Forms NU (Non-Upset) and EU (Upset)

product

Tubing Dimensions: 1.05” to 4-1/2” with End Processing Forms NU (Non-Upset) and EU (Upset)  You may also like

You may also like

2.

Petroleum Tubing: Specifications 1.05”-4-1/2” with End Processing Forms NU

(Non-Upset) and EU (Upset)

Petroleum

tubing is one of the essential devices in the process of oil extraction and

transportation. Its main function is to transport oil and natural gas from

underground to the surface. At present, the common specifications of petroleum

tubing on the market range from 1.05 inches to 4-1/2 inches, which can meet the

extraction requirements of different oil wells. There are mainly two types of

end processing forms for tubing: NU (Non-Upset) and EU (Upset). The NU end

processing form refers to no additional thickening treatment at the end of the

tubing. The advantage of this processing form is the lower cost, which is

suitable for some wells with lower strength requirements. The EU end processing

form, on the other hand, involves thickening the end of the tubing, which can

greatly increase the tensile and torsional strength of the tubing, enabling it

to better adapt to high-pressure and complex downhole environments.

Different

specifications and end processing forms of tubing have their own

characteristics in practical applications. For example, the small-diameter

tubing of 1.05 inches is usually used in some small oil and gas wells. Its

smaller diameter can reduce drilling costs, and in some areas with better

geological conditions, this specification of tubing can also meet the

extraction requirements. The large-diameter tubing of 4-1/2 inches is mainly

used for the extraction of large oil wells and deep wells, which need to

withstand greater pressure and flow. Therefore, the requirements for the

strength and sealing of the tubing are higher. When selecting petroleum tubing,

users need to make decisions based on the specific conditions of the oil well.

For example, in some oil wells containing corrosive gases, tubing with

anti-corrosion coatings should be selected; in high-pressure oil wells, tubing

with the EU end processing form should be chosen. In addition, the material of

the tubing is also very important. Common materials include carbon steel, alloy

steel, etc., and there are differences in performance and cost for tubing made

of different materials.

The

manufacturing process of petroleum tubing is also very strict and involves

multiple procedures, including inspection of raw materials, formation of the

tube body, end processing, and quality inspection. Each procedure must be

carried out strictly in accordance with national and industry standards to

ensure the quality and performance of the tubing. With the continuous progress

of science and technology, the manufacturing technology of petroleum tubing is

also constantly innovating. In the future, more high-performance and

high-reliability tubing products will be introduced to the market, providing

strong support for the sustainable development of the oil industry.

Welcome

to the Online Store of Tianjin Longkailai Petroleum Equipment Co., Ltd.

Specifications:

1.05”-4-1/2” with end processing forms NU (Non-Upset) and EU (Upset)

Execution

Standards: API-5CT, API-5L, API-5B, API 5D

Company

Products: Tubing couplings, tubing collars, thickened tubing couplings, flush

joint tubing couplings, variable thread tubing couplings, extended tubing

couplings, single-end threaded tubing couplings, internal thread tubing

couplings, tubing connectors, variable thread tubing connectors, variable

diameter tubing couplings, tubing conversion connectors, tubing coupling stock,

tubing nipples, tubing short sections, thickened tubing nipples, tubing lifting

nipples, double male tubing nipples, heavy-weight tubing nipples/short

sections, lifting tubing nipples/short sections, variable thread tubing

nipples/short sections, variable diameter tubing short sections/nipples, tubing

conversion connectors, single-end threaded tubing nipples, coupling stock,

thickened tubing, EUE thickened petroleum tubing, high-pressure tubing nipples,

[casing short sections], [casing nipples], [double male casing short sections],

[double male casing nipples], [casing variable thread couplings], [casing

variable thread connectors], [external thread casing nipples/short sections],

[casing conversion connectors], [high-pressure casing nipples], [casing thread

protectors (cap)], [casing coupling stock], [finished casing products], casing

couplings, coupling stock, short round thread casing couplings, long round

casing couplings, tapered casing couplings, variable thread casing couplings,

casing connectors, casing collars, variable diameter casing couplings,

eccentric casing couplings, casing conversion connectors, API casing,

single-end threaded casing couplings, coupling stock.

Casing

Specifications: 4-1/2”-20” with thread types such as STC (Short Round), LTC

(Long Round), BTC (Trapezoidal Thread), etc.

Tubing

Specifications: 1.05”-4-1/2” with end processing forms NU (Non-Upset) and EU

(Upset).

Custom

Processing: We can process couplings, nipples, variable thread connectors,

etc., in various lengths and sizes according to order drawings.

Processing

Forms: Straight connection tubing nipples/connectors, PIN * PIN (double male

nipples), PIN * BOX (one male one female finished nipples), BOX * PIN (one

female one male finished nipples).

Materials:

H40, J55, K55, N80, L80, C-90, C95, T95, P110, Q125, 13Cr-80, 13Cr-110, Super

13Cr, Nickel-based alloy tubing, etc.

Drill

Pipe Specifications: 2-3/8”-6-5/8”, etc.

Thickening

Forms: Internal thickening, external thickening, internal and external

thickening. Custom-made products such as drill pipe variable thread connectors,

drill pipe nipples, double male drill pipe nipples, and drill pipe conversion

connectors in various lengths according to orders or drawings.

Materials:

E-75, X95, G105, S135, etc.

Company

Philosophy: We adhere to the management philosophy of people-oriented and

customer-first. Based on advanced equipment and scientific management, we

provide high-quality products for customers. With a complete marketing network

and service system, we ensure satisfactory service for customers. Let's join

hands to create a brilliant future!

Dimensions, tolerances and masses of

API Buttress thread casing coupling

|

代号1 Label 1

|

规格a Size

|

外径 Outside diameter

|

最小 长度 Mini -mum length

|

镗孔直径 Diameter of Counter -bore

|

承载面 宽度 Width of bearing face

|

重量 Mass kg |

|

||

|

外径 Outside diameter

|

标准 接箍 Regular

|

特殊间隙接箍 Special clearance

|

|

||||||

|

|

|||||||||

|

D mm |

W mm |

WC mm |

NL mm |

Q mm |

b mm |

标准接箍 Regular

|

特殊间隙 接箍 Special clearance

|

|

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

|

4-1/2 5 5-1/2 6-5/8 7 7-5/8 8-5/8 9-5/8 10-3/4 11-3/4 13-3/8 16 18-5/8 20 |

114.30 127.00 139.70 168.28 177.80 193.68 219.08 244.48 273.05 298.45 339.72 406.40 473.08 508.00 |

127.00 141.30 153.67 187.71 194.46 215.90 244.48 269.88 298.45 323.85 365.12 431.80 508.00 533.40 |

123.82 136.52 149.22 177.80 187.32 206.38 231.78 257.18 285.75 - - - - - |

225.42 231.78 234.95 244.48 254.00 263.52 269.88 269.88 269.88 269.88 269.88 269.88 269.88 269.88 |

117.86 130.56 143.26 171.83 181.36 197.23 222.63 248.03 276.61 302.01 343.28 410.31 476.99 511.91 |

3.18 3.97 3.97 6.35 5.56 7.94 9.52 9.52 9.52 9.52 9.52 9.52 9.52 9.52 |

4.55 5.85 6.36 11.01 10.54 15.82 20.86 23.16 25.74 28.03 31.77 40.28 62.68 50.10 |

3.48 4.00 4.47 5.65 6.28 9.29 10.80 12.02 13.39 - - - - - |

|

|

对于第1、2和3组,外径W的公差为±1%,但不大于±3.18mm。 1 % but not larger Groups 1, 2 and 3 — Tolerance on outside diameter W is ± 3,18 mm. than ±对于第4组,外径W的公差为±1%,但不大于+3.18 –1.59mm。 Group 4 — Tolerance on outside diameter W, is ±1 % but not larger than +3.18 –1.59mm. a. 接箍的规格代号和相应的管子规格代号相同。 The coupling specification label is the same as the corresponding pipe specification label. |

|

||||||||

No comments available at the moment

No comments available at the moment

share

share

service

service

top

top

Store Center

Store Center

All Exhibitor Categories

All Exhibitor Categories

Exploration & Production

Exploration & Production

Engineering Technical

Engineering Technical

Engineering Construction

Engineering Construction

Equipment Manufacturing

Equipment Manufacturing

Natural Gas & Pipelines

Natural Gas & Pipelines

Oilfield Digitization

Oilfield Digitization

New Energy

New Energy

Petrochemical Products

Petrochemical Products

Logistics Transportation

Logistics Transportation

Equipment&Hardware

Equipment&Hardware

wechat sharing

wechat sharing

link sharing

link sharing

Global Links

Global Links  Accurate Matching

Accurate Matching  Online Interaction

Online Interaction  Brand Enhancement

Brand Enhancement  All-Win Cooperation

All-Win Cooperation  Official account

Official account  Mobile terminal

Mobile terminal